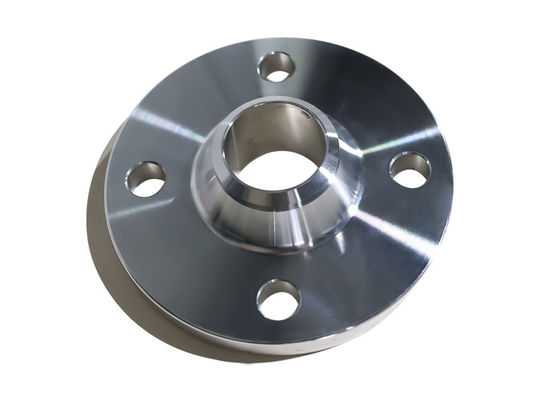

Flat Welded Steel Pipe Flange With Neck

INTRO

This flange type is used, normally, in high-pressure and high/low temperatures applications that require an unrestricted flow of the fluid conveyed by the piping system (the bore of the flange matches with the bore of the pipe).

Standard:

GB/T9119-2010 HG/T20592-2009 HG/T20615-2009 DIN ASME BS JIS

Material:

304:F304 S30408 S30408II S30408III S30400

304L:S30403 S30403II 30403 30403II

316L:31603 31603II 31603III

2507(F53) 2205(F51) TP310S(06Cr5Ni20) TP321(06Cr18Ni11) S22053III=2205III T321-32168=321

A welding neck flange (“WN”)features a long tapered hub that can be welded with a pipe, ensuring strength and smooth fluid flow while minimising turbulence and erosion at the joint. The welded neck design offers a secure connection, making it suitable for applications involving high pressure and temperature.

This flange is built for durability and ease of installation, fitting both standard and custom pipe sizes. It is commonly used in industries such as oil and gas, chemical processing, power generation, and water treatment.

Why Choose Our Weld Neck Flange?

Reliable Strength and Stability: The flange’s short tapered hub ensures a gradual transition from the flange to the pipe, reducing stress and providing reliable strength in high-pressure and high-temperature environments.

Optimised Fluid Dynamics: Designed to minimise turbulence and erosion at the joint, the flange supports smooth fluid flow, contributing to the efficiency and longevity of the piping system.

Secure and Durable Connection: offers a strong and stable connection, reducing the risk of leaks and ensuring the integrity of the piping system.

Versatile Material Options: Available in 304, 304L, 316L stainless steels, and high-strength alloys like 2507 and 2205.

Compliance with International Standards: Manufactured to meet rigorous standards, including GB/T9119-2010, HG/T20592-2009, DIN, ASME, BS, and JIS.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!