Tailor-made for HVAC dampers, ventilation panels, and non-locking rotary systems

This page provides dedicated information about our custom rotary cable options. For full product specifications and structure overview, please visit the Rotary Control Cable Main Page.

Why Choose Phidix for Custom Rotary Cable Design?

Phidix supports OEMs, system integrators, and equipment manufacturers needing tailored rotary control cable solutions beyond off-the-shelf offerings.

Whether you require:

• A specific panel mount interface

• A non-standard stroke angle

• Or a compact routed design for limited space,

• Our engineering team will configure a solution that balances durability, cost, and installation efficiency.

What You Can Customize

| Category |

Options Available |

| Input Shaft |

Brass standard / Optional stainless steel / Anti-backlash types |

| Head Tube & Housing |

Molded / Sealed / High-temp variants |

| Inner Cable Material |

Stainless wire in multiple gauges (.054" default) |

| End Fittings |

Loop end / Crimped rod / Flat tab or ball joint ends |

| Conduit Type & Cover |

Plastic, aluminum cap, optional flame-retardant coatings |

| Stroke Angle |

Standard ±45° / Custom sweep up to 90° each direction |

| Panel Nut Interface |

Threaded / Locking ring / Quick-insert |

| Total Cable Length |

Up to 3 meters or per layout drawing |

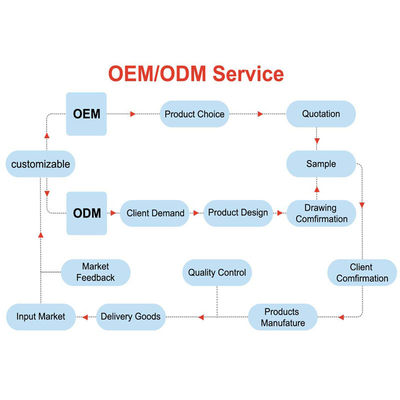

How Custom Ordering Works

1.Define Your Specs

Send us your drawings, part references, or describe your use case (e.g. damper location, space limitations).

2.Engineering Review

Our engineers will confirm feasibility, recommend specs, and provide a draft model or configuration sheet.

3.Prototype or Batch Production

Low-volume sampling or full OEM production with IATF 16949-level quality control.

4.Delivery & Support

Global shipment + application feedback loop to refine configuration if needed.

Perfect for These Scenarios

• Custom industrial HVAC units needing precise panel actuation

• Truck cabin ventilation with confined panel spaces

• Non-locking control systems where backdrive is unacceptable

• Marine or outdoor enclosures requiring corrosion resistance

• Replacement cables for legacy systems with discontinued part numbers

Ready to Build Your Cable?

Phidix works with OEMs, HVAC manufacturers, and maintenance teams across sectors.

Let us know:

• Required input/output ends

• Operating environment (temperature, exposure)

• Length & routing constraints

• Quantity & delivery timelines

We'll return:

• Technical drawing / quote

• Configuration plan

• Lead time for prototyping or delivery

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!