Pull-Only Clutch Cable for Buses & Trucks – Heat-Resistant, Vibration-Tested, Fleet-Proven

This page is a focused technical extension of our Clutch Cable Overview, detailing our high-temperature and high-vibration clutch cable variants for bus and heavy truck use.

Purpose-Built for Harsh Commercial Duty Cycles

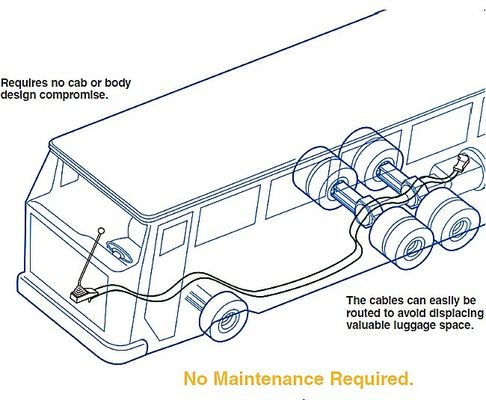

In transit fleets like Yutong buses, King Long coaches, and FAW/Sinotruk trucks, clutch cables must survive more than just daily use. They endure:

• Constant stop-start actuation in traffic

• Engine bay heat exposure up to 120°C

• Long-stroke pedal cycles over hundreds of kilometers per day

• Frame vibration from diesel engines and uneven roads

Phidix Pull-Only Clutch Cables are engineered to meet these harsh realities.

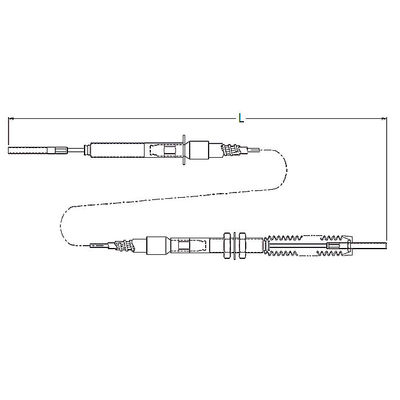

Internal Structure Tailored for Performance

Layered Protection & Flex-Ready Build

| Component |

Description |

| Core Wire |

Nylon-coated 7×7 stainless steel for fatigue resistance |

| Conduit Wrap |

Steel inner coil + flexible PP jacket (or PVC for cost-sensitive) |

| Outer Sheath |

Flame-retardant black vinyl or heat-resistant polypropylene |

| End Termination |

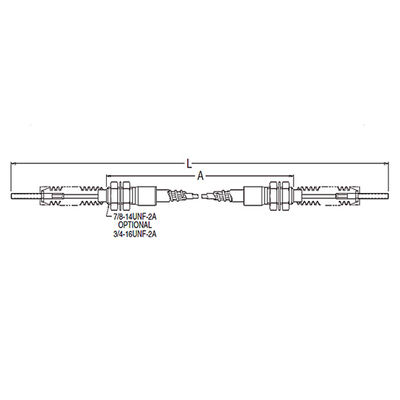

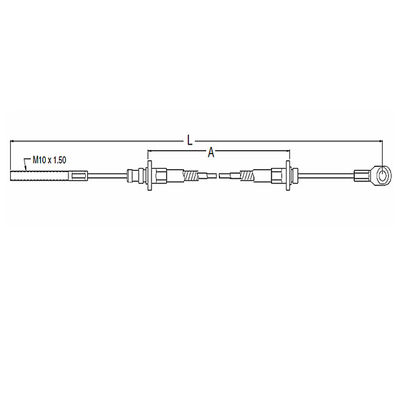

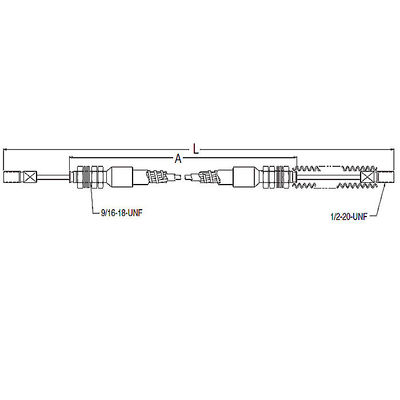

CA270, CA235, CA312, A183, clevis head, threaded rod |

| Optional Boot/Grommet |

Seals against water, dust, and engine fluids |

⇒ Lab-tested to >300,000 full-stroke operations with <1.5mm backlash increase.

Real-World Applications by Vehicle Type

| Vehicle Type |

Use Case Description |

Common Configs |

| Yutong Buses |

Clutch pedal to bellcrank linkage |

CA235-A-L / CA312-A-L |

| FAW Trucks |

Long-stroke clutch actuator with dual routing bends |

CA270-XXX / A183 Series |

| Shuttle Vans |

Under-dash clutch cable replacement |

CA236-A-L |

Contact us for chassis compatibility & drawing validation.

FAW vs Yutong Operational Case Highlights

| Scenario |

Challenge |

Phidix Solution |

| Urban bus in humid climate (Yutong) |

Thermal soak, short-stroke fatigue |

PP jacket + corrosion-proof clevis |

| Plateau truck in cold mornings (FAW) |

-30°C startup stiffness |

Nylon core + low-friction sheath + booted ends |

OEM Integration & Retrofit Support

Phidix supports both:

OEM Integration with clevis, spherical, or bolt-mount ends

Fleet Retrofitting with adjustable length options, bracket-ready terminals

CAD matching and fitment drawings available.

Frequently Asked Questions (FAQ)

Q1: What temperature ranges are supported by this cable?

A: Operating temperatures from –30°C to +120°C are standard. We also offer high-temp upgrades upon request.

Q2: Can this be used with non-Phidix control heads?

A: Yes. End fittings follow industry common sizes and thread specs. Custom interfaces available.

Q3: How is this different from the universal clutch cable?

A: This version is specifically optimized for harsh-duty fleet environments, with stainless variants and tighter backlash tolerance.

Cross-Linking and Return Path

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!