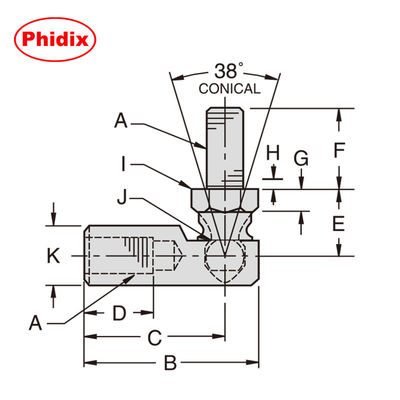

R - G Series Stainless Steel Ball Joint , Steel Housing , Staked Design With Rubber Grommet

Product Description

The R-G Series features a robust, cost-effective metal-to-metal ball joint design engineered for medium to heavy-duty applications. Constructed from low-carbon steel, the precision heat-treated ball stud and body ensure exceptional strength and wear resistance. Components are zinc-plated with a yellow dichromate coating for superior corrosion protection and uniform aesthetics. The heat-treated ball is securely crimped into the shell, enabling smooth, controlled movement with minimal play. A reinforced rubber grommet seal enhances durability by shielding against contaminants. Ideal for automotive, industrial, and machinery use, R-G ball joints deliver reliable performance, combining economical value with long-term durability. Their precision engineering ensures consistent operation under demanding conditions, making them a preferred choice for OEMs and aftermarket applications requiring high load capacity and environmental resilience.

Technical Parameters

| Product Name |

R-G Series Ball Joints |

| Material |

Ball Stud –

• Low carbon steel, case hardened

• Zinc plated, clear dichromate treated

Body –

• Low carbon steel, case hardened

• Zinc plated, clear dichromate treated |

| Features |

• Steel body and ball stud "staked" design offers an economical solution to medium to heavy-duty ball joint applications

• Ball stud is case hardened for extended wear life

• Rubber grommet provides a durable sealagainst contaminants

• Can be used in a wide range of temperatures:-30°F — 250°F(-34°C — 121°C)

• Custom sizes and assemblies can be built to your specifications, including:

- male to male or female tofemale

- right or left-handed threads

• Many metric sizes available — consult factory

• Meets SAE specification J490 (Type G/Style 2) |

| Brochure |

Free samples are available if all sizes are the same as what we have available, if not, please contact me for a cost effective solution |

| Belivery Time |

7-40 working days |

| Applications |

Various integral ball joint applications, including:

• Lawn and garden equipment

• Construction

• Industrial equipment |

| Specification |

R-G_Ball Joint.pdf |

| Other Related Products |

S / SS / SC Series Metal Ball Joint

SR - G Series Stainless Steel Ball Joint

|

Real Picture

OEM/ODM

Production Process

Packing and Shipping

A.Packing

Usually according to the specific size of the product to arrange the packaging, small goods are packed in cardboard boxes, large goods are packed in cardboard boxes + wooden pallets, or one-piece paper pallets, if you have special needs, please contact us, we will try our best to serve you!

|

cardboard boxes

(small goods)

|

cardboard boxes+wooden pallets

(large goods)

|

one-piece paper pallets

(large goods)

|

|

|

|

B.Shipping

We have cooperated with the world's major logistics companies, you can choose the logistics mode that suits your needs, so that the goods can arrive within the specified time.

| Logistic Company |

|

|

|

|

|

| Mode of Transportation |

Land, sea and air transportation |

C.Payment Methods

Note:If you need another payment method, please contact us.

About us

Your Professional Control Cable Manufacturer!

Phidix Motion Controls (PMC) started the business in 2004,CMC Provides a diverse range of high-end drive control products and engineered solutions. The product line includes various sizes of control flex shafts, cab units and a range of standard parts for a wide range of high-end industrial customer markets.

| Why choose us |

|

Patent Certificate

|

Reasonable Prices

|

|

The company's products have passed the IATF16949 patent certificate, which ensures the quality of the products.

|

High quality + factory price + fast response+reliable service is what we try our best to provide for you.

|

|

Rapid Delivery

|

ODM/OEM

|

|

We have all the styles you need in stock and can deliver on short notice.

|

When you make a request, our engineers provide you with a faster and better solution based on your needs.

|

FAQ

Q: How do you design control cables?

A: We must first understand your application and must consider many factors, such as length, outside diameter, working input force, maximum input force, travel, housing material, requirements for the wire rope, material of the terminal fittings (carbon steel or stainless steel), etc.

Q: How do I place my order?

A: We produce according to the specifications, drawings or samples provided by the customer.

Q: Is the quality of your product good? How can I trust you?

A: We are a professional manufacturer of wire assemblies with more than 10 years of production experience in China. We have been providing first-class service and quality products to make our customers successful. Please contact our sales department and let us know what we can do for you, trust us, we won't let you down.

Q: What is the lead time for my order?

A: This depends a lot on the size of your order. Usually 15 days. If you need it urgently, we will do our best to fulfill your request.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!