Durable Material Push Pull Standard Industrial Mechanical Control Cable Assembly

Product Description

Push Pull Control Cable is a versatile, essential component for mechanical and industrial applications. It transmits both push and pull forces, making it perfect for control systems requiring precise movement. Known for its durability, this high-quality cable withstands harsh environments and heavy use. Its flexible design allows for easy installation in tight spaces, making it a favorite for complex machinery. Whether you're working with industrial equipment or mechanical systems, Push Pull Control Cable is a reliable choice.

Technical Parameters

| Pseudolaric acid |

Push-Pull Standard Assemblies |

| Innermember |

Made of flexible 1 x 19 carbon strand and armored with a swaged steel jacket |

| Coatings |

PA / PU |

| Accessory |

Lubrication,End Rods,Wiper Seals,Support Tube and Swivel Seal,Conduit Caps |

| Lengths |

Based on specific requirements |

| Brochure |

Free samples are available if all sizes are the same as what we have available, if not, please contact me for a cost effective solution |

| Belivery Time |

7-40 working days |

| Minimum order quantity |

1 piece |

| Applications |

• Implement control

• Throttle control

• PTO/4WD activation

• Valve actuation

• Remote battery disconnect

• Remote electrical disconnect

• Transmission shift

• Hydrostatic drives

• Latches |

| Specification |

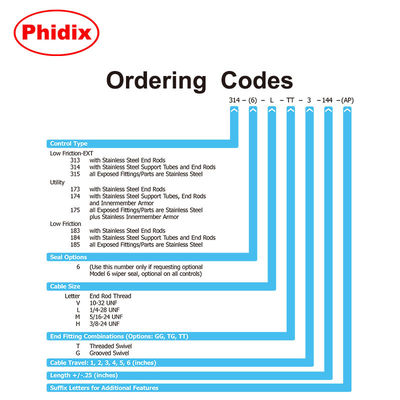

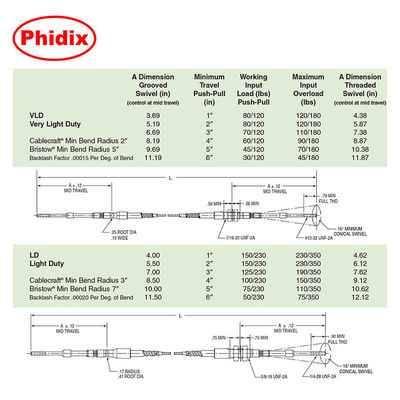

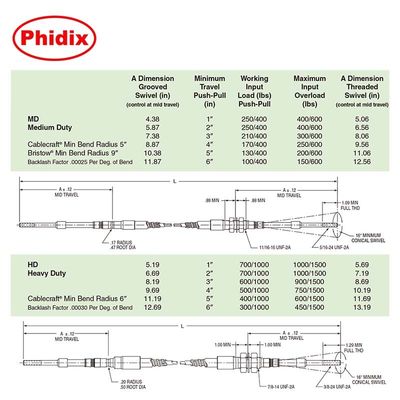

Push-Pull_Standard_Industrial.pdf |

Real Picture

OEM/ODM

Production Process

Packing and Shipping

A.Packing

Usually according to the specific size of the product to arrange the packaging, small goods are packed in cardboard boxes, large goods are packed in cardboard boxes + wooden pallets, or one-piece paper pallets, if you have special needs, please contact us, we will try our best to serve you!

|

cardboard boxes

(small goods)

|

cardboard boxes+wooden pallets

(large goods)

|

one-piece paper pallets

(large goods)

|

|

|

|

B.Shipping

We have cooperated with the world's major logistics companies, you can choose the logistics mode that suits your needs, so that the goods can arrive within the specified time.

| Logistic Company |

|

|

|

|

|

| Mode of Transportation |

Land, sea and air transportation |

C.Payment Methods

Note:If you need another payment method, please contact us.

About us

Your Professional Control Cable Manufacturer!

Phidix Motion Controls (PMC) started the business in 2004,CMC Provides a diverse range of high-end drive control products and engineered solutions. The product line includes various sizes of control flex shafts, cab units and a range of standard parts for a wide range of high-end industrial customer markets.

| Why choose us |

|

Patent Certificate

|

Reasonable Prices

|

|

The company's products have passed the IATF16949 patent certificate, which ensures the quality of the products.

|

High quality + factory price + fast response+reliable service is what we try our best to provide for you.

|

|

Rapid Delivery

|

ODM/OEM

|

|

We have all the styles you need in stock and can deliver on short notice.

|

When you make a request, our engineers provide you with a faster and better solution based on your needs.

|

FAQ

Q: How do you design control cables?

A: We must first understand your application and must consider many factors, such as length, outside diameter, working input force, maximum input force, travel, housing material, requirements for the wire rope, material of the terminal fittings (carbon steel or stainless steel), etc.

Q: How do I place my order?

A: We produce according to the specifications, drawings or samples provided by the customer.

Q: Is the quality of your product good? How can I trust you?

A: We are a professional manufacturer of wire assemblies with more than 10 years of production experience in China. We have been providing first-class service and quality products to make our customers successful. Please contact our sales department and let us know what we can do for you, trust us, we won't let you down.

Q: What is the lead time for my order?

A: This depends a lot on the size of your order. Usually 15 days. If you need it urgently, we will do our best to fulfill your request.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!